KORLOY has newly launched the Super Endmill for HRSA 6F, optimized for machining heat-resistant super alloys.

Heat-resistant super alloys (HRSA), widely used in aircraft engines and power generation turbine parts, are classified as very difficult-to-machine materials due to their high strength at elevated temperatures and low thermal conductivity.

The low thermal conductivity concentrates the heat generated during machining on the cutting edge, causing rapid tool wear and chipping. This also limits the cutting speed when machining HRSA.

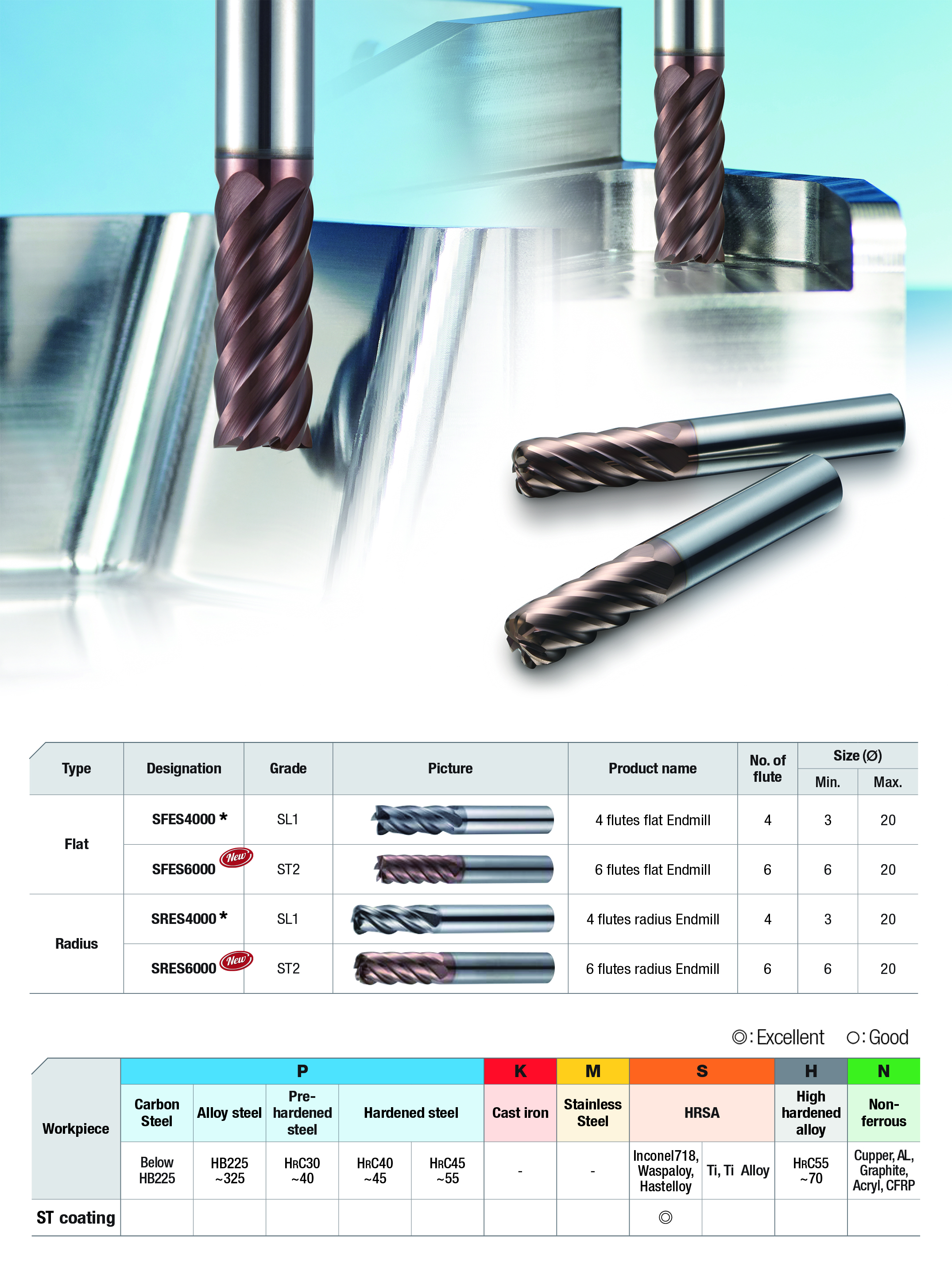

To solve these problems, KORLOY has released the Super Endmill for HRSA 6F.

The Super Endmill for HRSA 6F features positive rake angles and unequal spacing for excellent machinability and stability. A newly developed ST thin film with superior thermal barrier properties suppresses chipping and wear at the cutting edge during HRSA machining, thereby improving tool life.

Compared to a 4-flute tool, the increased 6 flutes enable high-efficiency machining at higher feed rates, contributing to improved productivity for our customers.