what you’ve wanted for an innovative tooling solution.

• Optimal for difficult-to-cut materials machining due to reduced cutting heat and enhanced chip evacuation

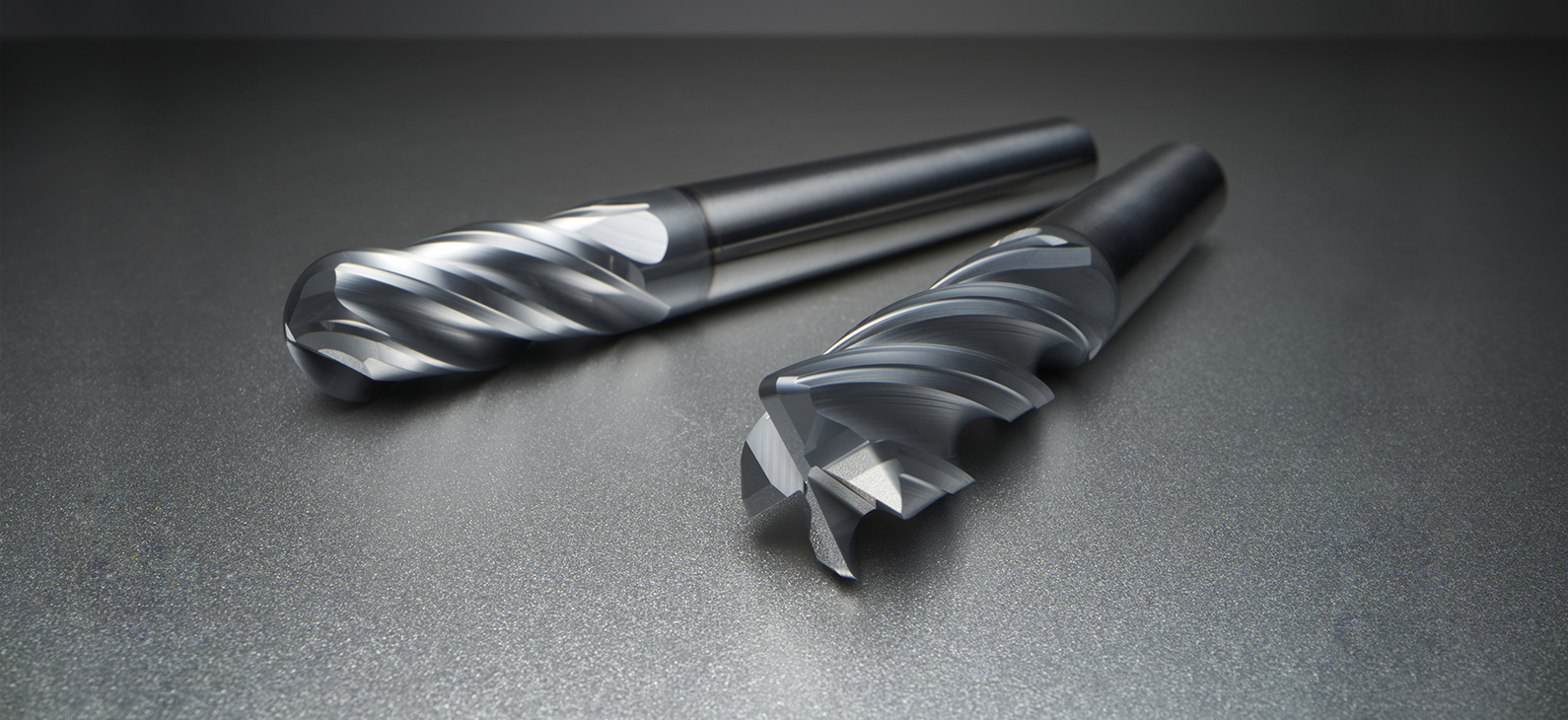

Super Endmill For Ti

KORLOY newly launched Super Endmill For Ti specializing in titanium and stainless steel.

Recently, the use of hard-to-cut material is increasing in various industries such as automobile, aerospace, and medical, which require high performance and miniaturization of products.

The representative hard-to-cut materials are titanium and stainless steel and it has features of low thermal conductivity and corrosion resistance. It is the main cause of hard to cut material and it causes problems such as short tool life and low productivity. In order to solve it, KORLOY newly launched Super Endmill For Ti specializing in titanium and stainless steel.

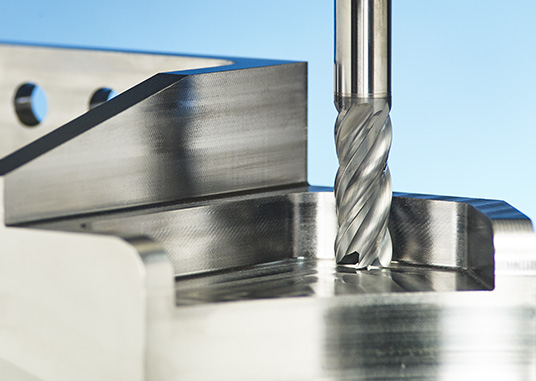

Super Endmill ensures excellent tool life, preventing fracture on cutting edge and increasing wear resistance in machining due to high toughness carbide substrate and new coating. By applying a positive rake angle, cutting load and high temperature are reduced to suppress work hardening. The flute design with large chip pockets improves chip evacuation problems and facilitates coolant supply, improving high temperature problems. The new grade of high-toughness substrate and high-lubrication coating prevents edge chipping and tool damage, and suppresses welding to ensure excellent tool life.

KORLOY' Super Endmill For Ti is optimized for stainless steel and titanium alloy machining, it provides the best solution on Hard to cut material with Super Endmill For HRSA together.

• Improved chip evacuation and long tool life

- Large chip pocket and streamlined flute design

- Sharp cutting edge optimal for difficult-to-cut materials cutting

- High lubrication coating layer and high toughness substrate

.jpg)

.jpg)

_2_retouch.jpg)

_1_retouch.jpg)

_3.jpg)