what you’ve wanted for an innovative tooling solution.

• Available for various workpieces such as mild steel and non-ferrous metals

SSD-N

The non-ferrous metals (aluminum and copper etc.) having lower melting point than other metals causes welding to easily occur in machining. That dulls the cutting edge of the tool and lowers the surface finish and chip evacuation and increases the cutting load which causes unexpected chipping and breakage of tools.

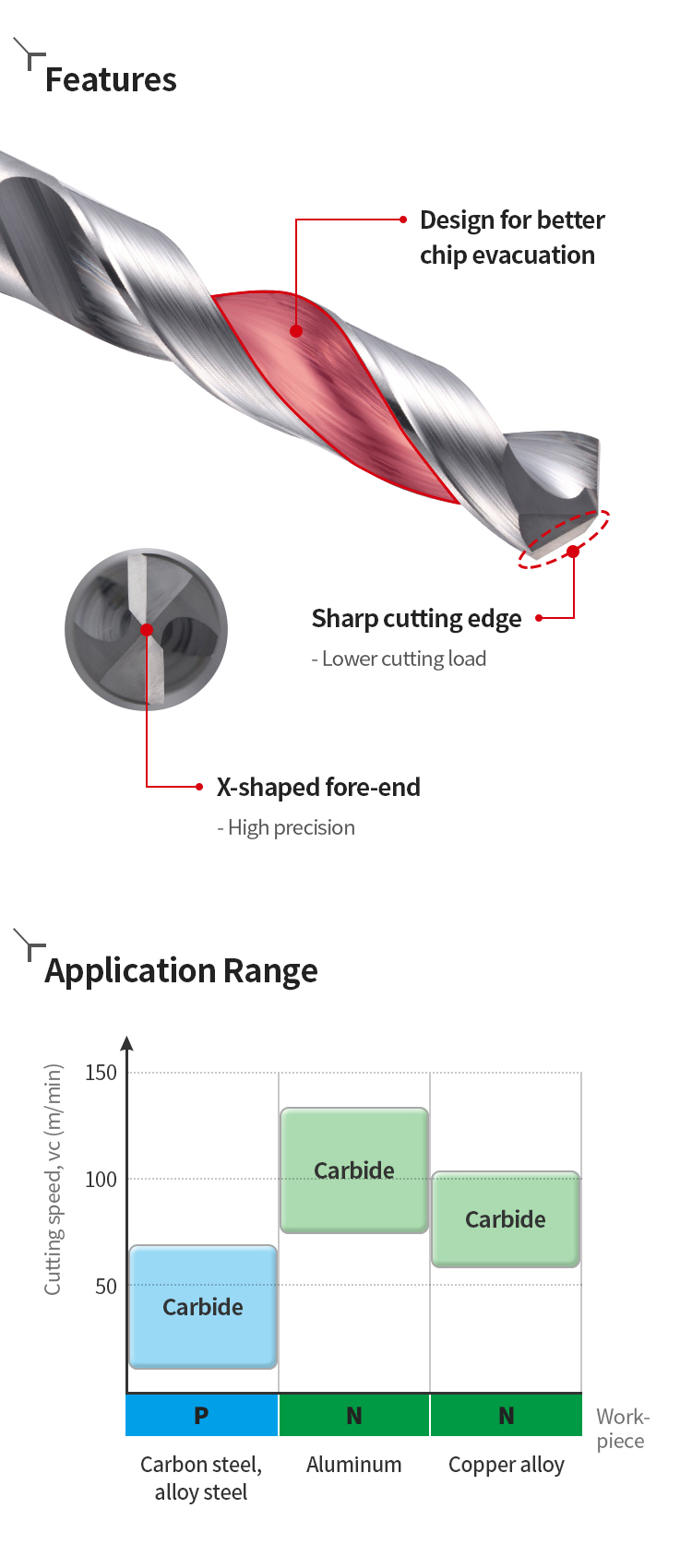

KORLOY launches a new drill for high performance in non-ferrous metals drilling. The SSD-N with sharp cutting edge minimizes welding. In addition, the design for better chip control and X-shaped thinning increases machinability and chip evacuation drastically.

The SSD-N drill increases your productivity by stable machinability in machining of non-ferrous metals and mild steel etc.

ㆍGood surface finish

- Minimized welding in machining from the sharp cutting edge

ㆍBetter chip evacuation

- The design for reinforced chip control

ㆍImproved machinability

- Lower cutting load by applying the X-shaped thinning

ㆍVarious workpiece machining

- Non-ferrous metals and mild steel etc.

.jpg)