what you’ve wanted for an innovative tooling solution.

• Increased productivity due to high speed capability

- Excellent surface finish and perpendicularity with high-precision products

• Excellent Clamping Stability

- Satisfactory clamping force of inserts by the use of the key shape

Pro-V Mill

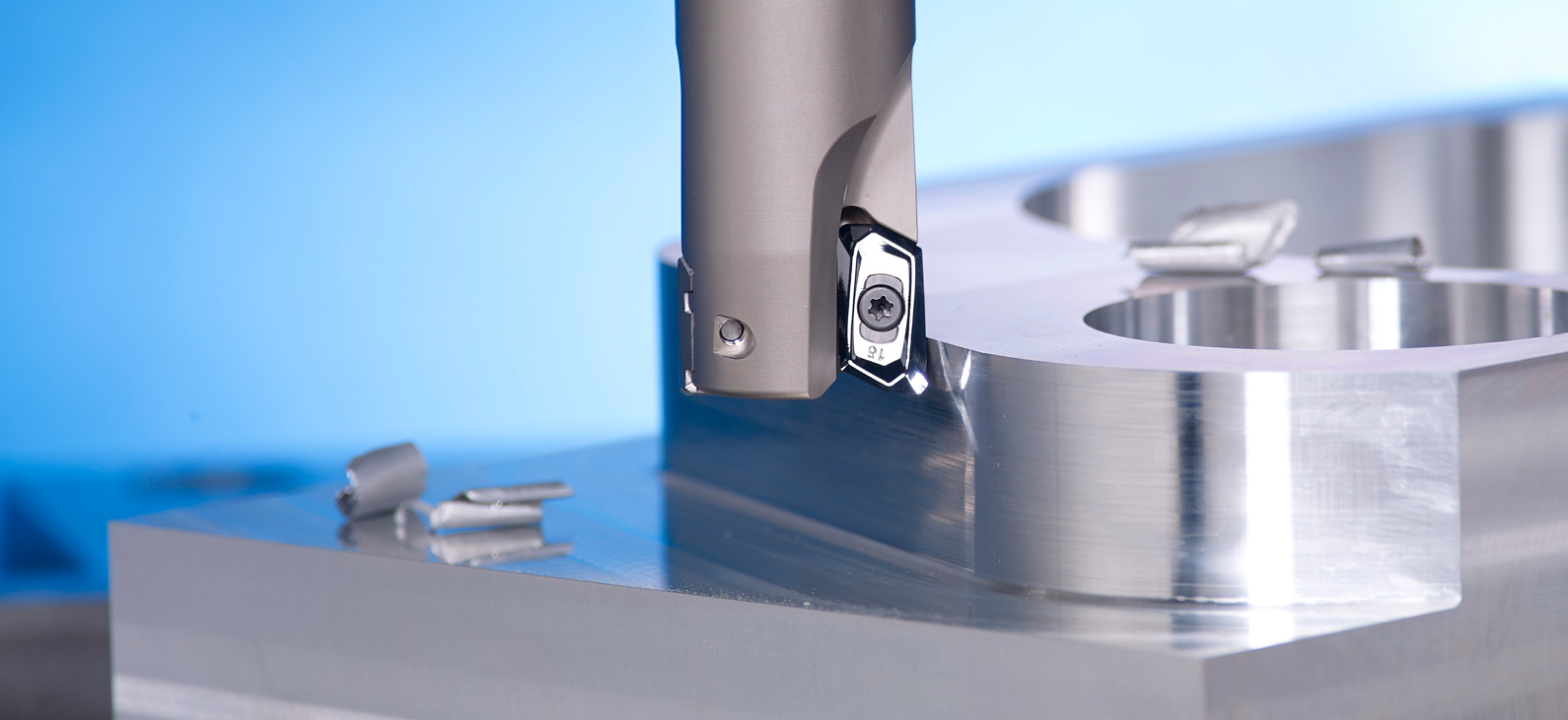

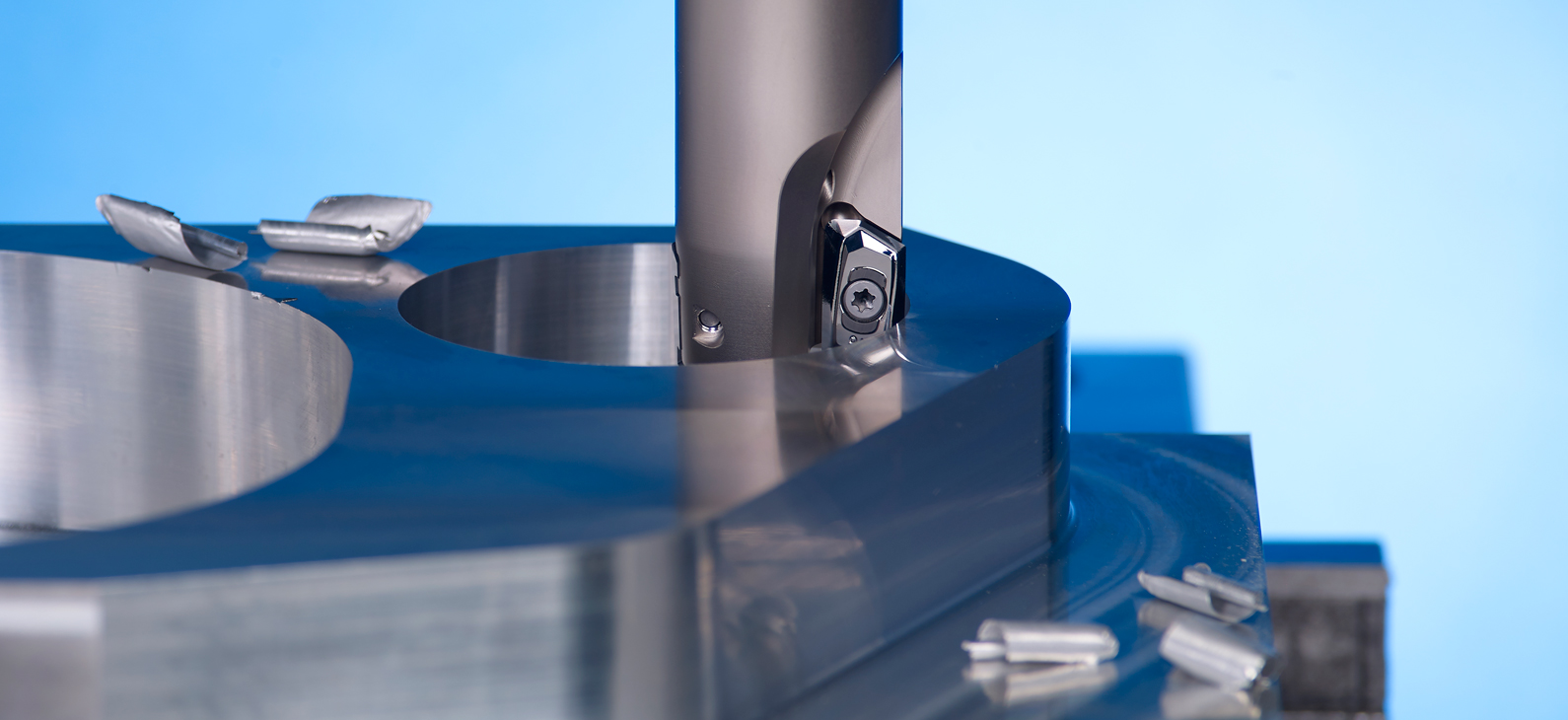

KORLOY introduces a new premium milling product line for aluminum, Pro-V Mill. Development of this product has allowed high speed capability in aluminum machining, leading to an immense increase in productivity.

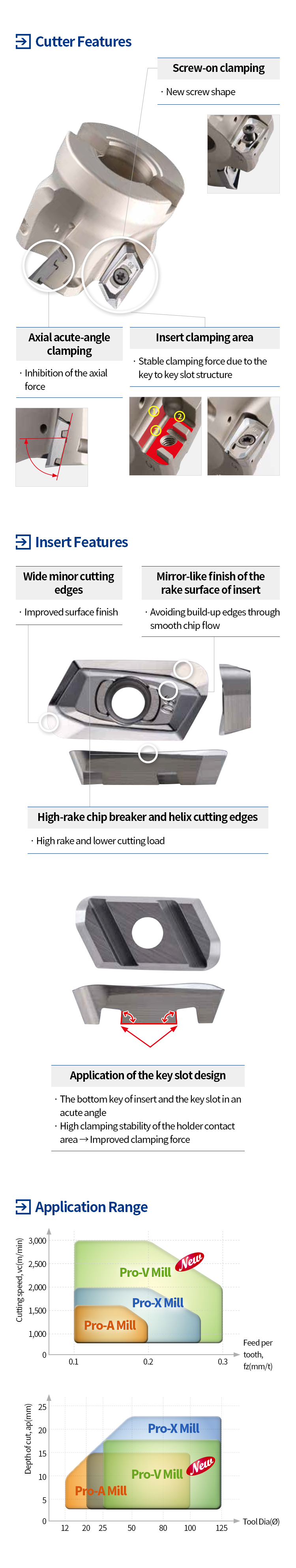

The huge impact given during high speed machining would change the position of the insert and cause tool breakage consequently. And the existing clamping method was not able to endure this impact. To overcome this kind of limit, a new clamping system has been applied. This new clamping method features enhanced clamping force at high speeds, providing reliable machining stability even when inserts get a shock.

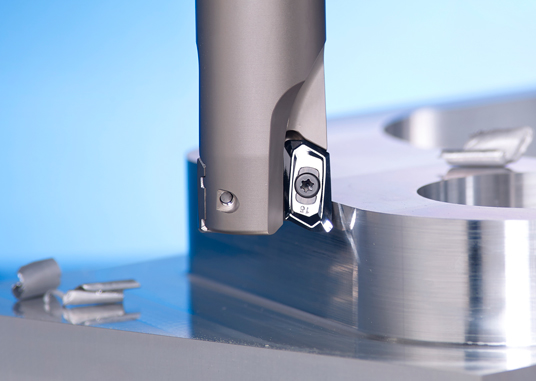

KORLOY applied a new key to key slot clamping system to our new product, Pro-V Mill, in order to increase the clamping force. With stable cutting performance at high speed, it remarkably improves productivity and surface finish compared to the existing products. Furthermore, the rake surface of the insert was treated with a mirror-like finish to avoid built-up edge issues. Various nose radius inserts are available to meet the needs of different applications.

Combined with the highly lubricative DLC grade PD1010, Pro-V Mill can improve the surface finish and product life.

ㆍExcellent clamping stability

- Strong clamping force at high speeds

- Reduced vibrations and noises

ㆍAdvanced productivity

- Higher table feed due to increased rpm

ㆍImproved surface finish

- Enhanced surface roughness and perpendicularity due to high speed capability

.jpg)