what you’ve wanted for an innovative tooling solution.

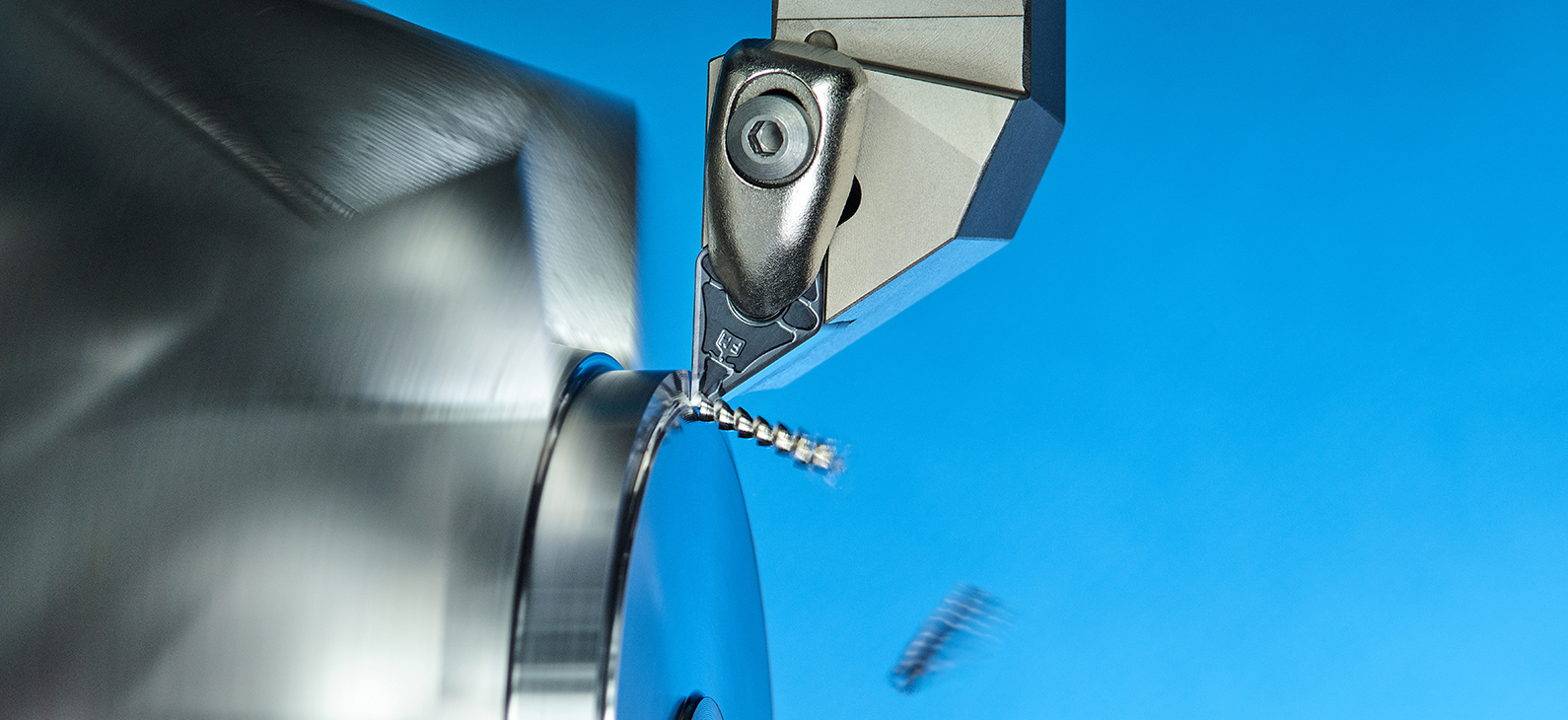

• Securing stable chip management with a side V-shaped cutting edge and concave projection design

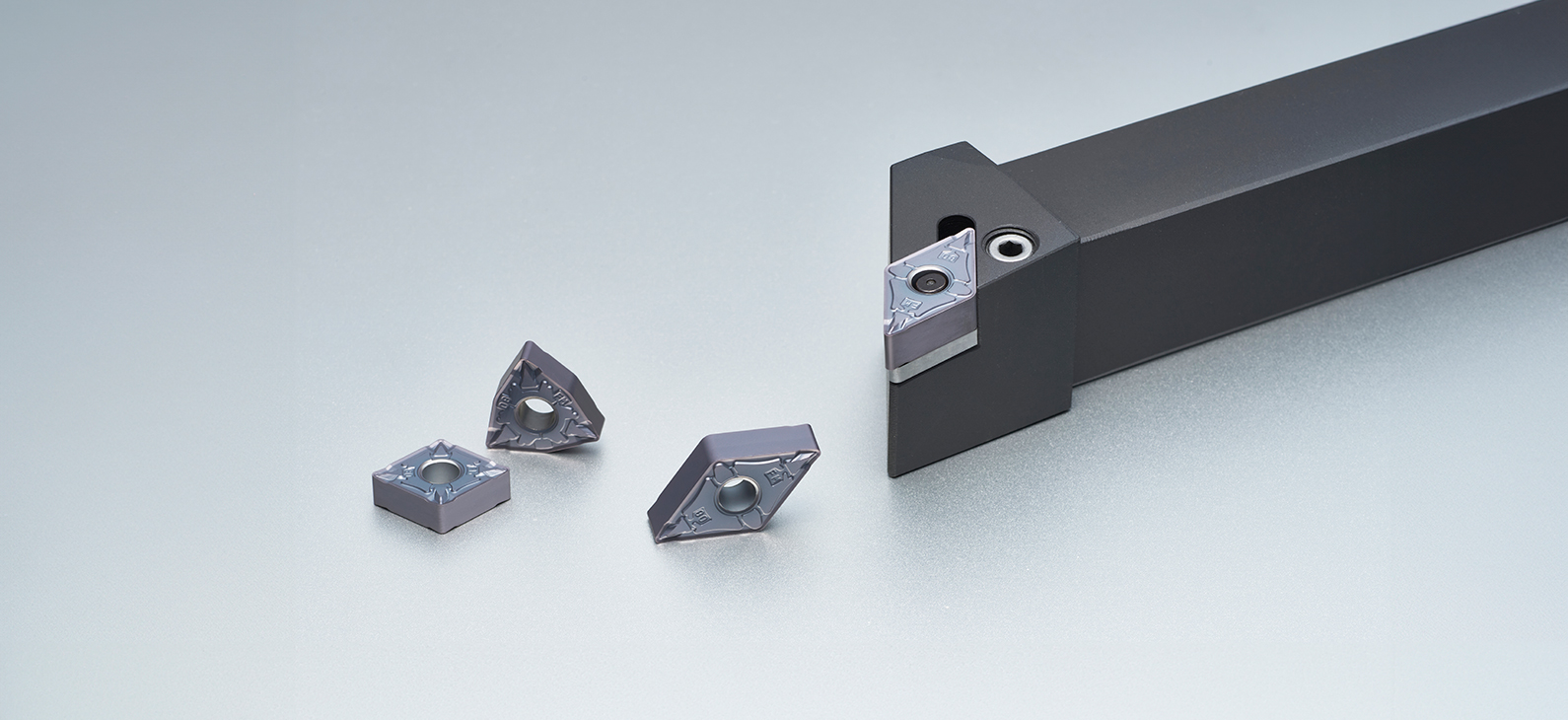

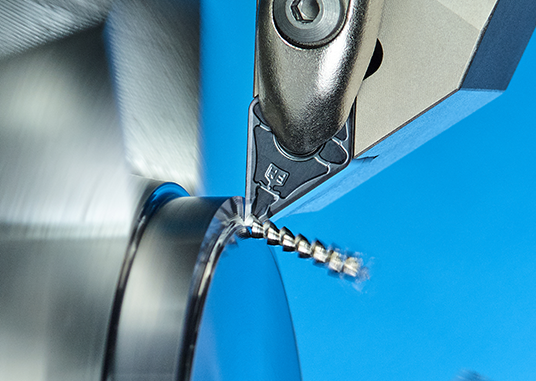

FM Chip Breaker (Negative)

Stainless steel, known for its excellent toughness and corrosion resistance, is widely used in various industries such as aerospace and automotive. However, it is considered to be a hard-to-machine material since the cutting process often causes severe work hardening, chip adhesion, and high shear resistance, leading to issues such as tool wear, reduced tool life, and chip entanglement. As a result, precise techniques and optimized tool selection are essential for machining stainless steel.

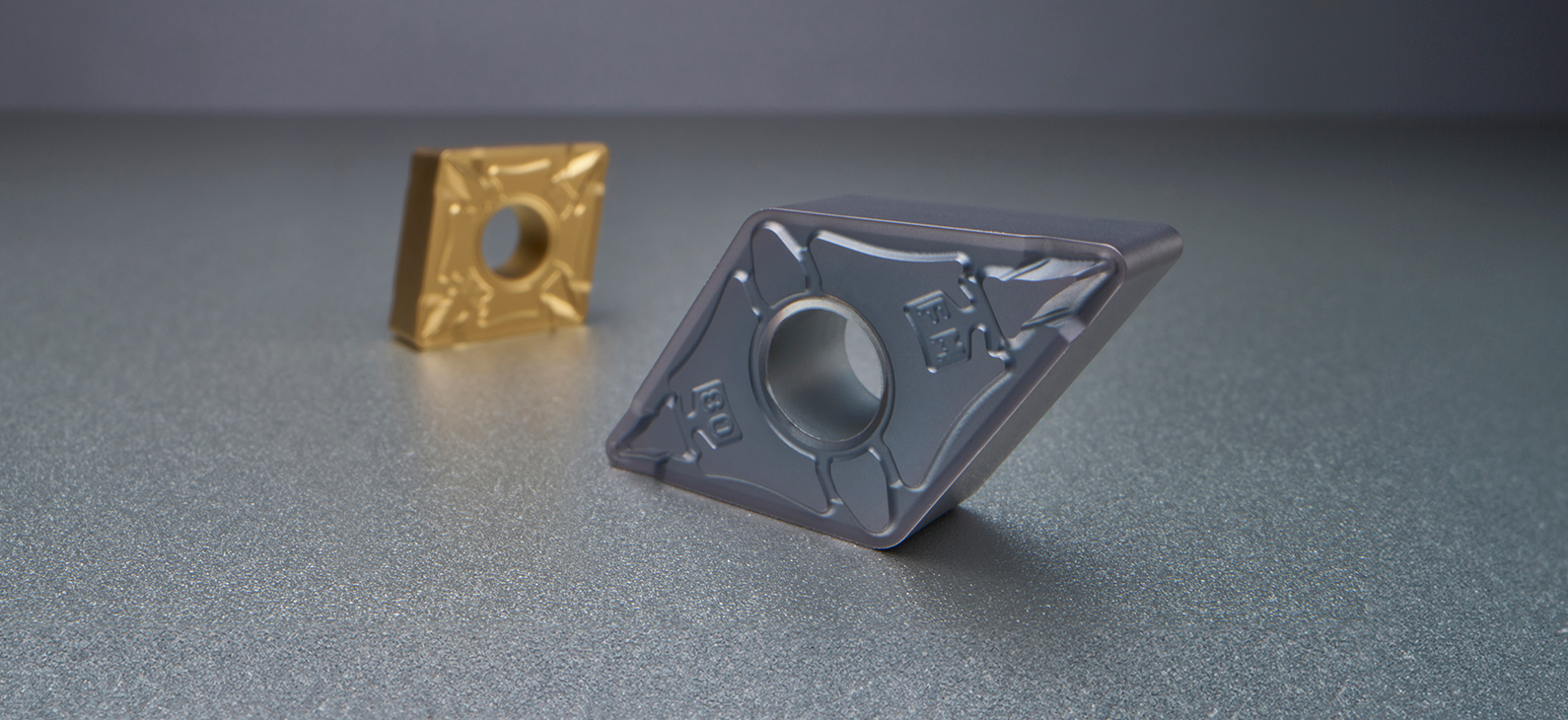

KORLOY has launched the FM chip breaker, featuring an optimized cutting edge design and advanced anti-welding technology for finishing stainless steel. This innovation significantly improves tool life and ensures stable chip control.

The FM chip breaker maximizes chip management during low depth-of-cut and low feed machining with its side V-shaped cutting edge and concave projection design. The anti-welding suppression geometry on the bottom dramatically enhances tool life when machining stainless steel. In addition,

due to its high manufacturing quality, it offers outstanding dimensional accuracy.

Furthermore, the FM chip breaker is also an optimal solution for machining difficult-to-cut materials. By applying a variable land design to secure rigidity at the vulnerable engagement boundary, it effectively prevents chipping and breakage, simultaneously achieving stable tool life and an excellent surface finish.

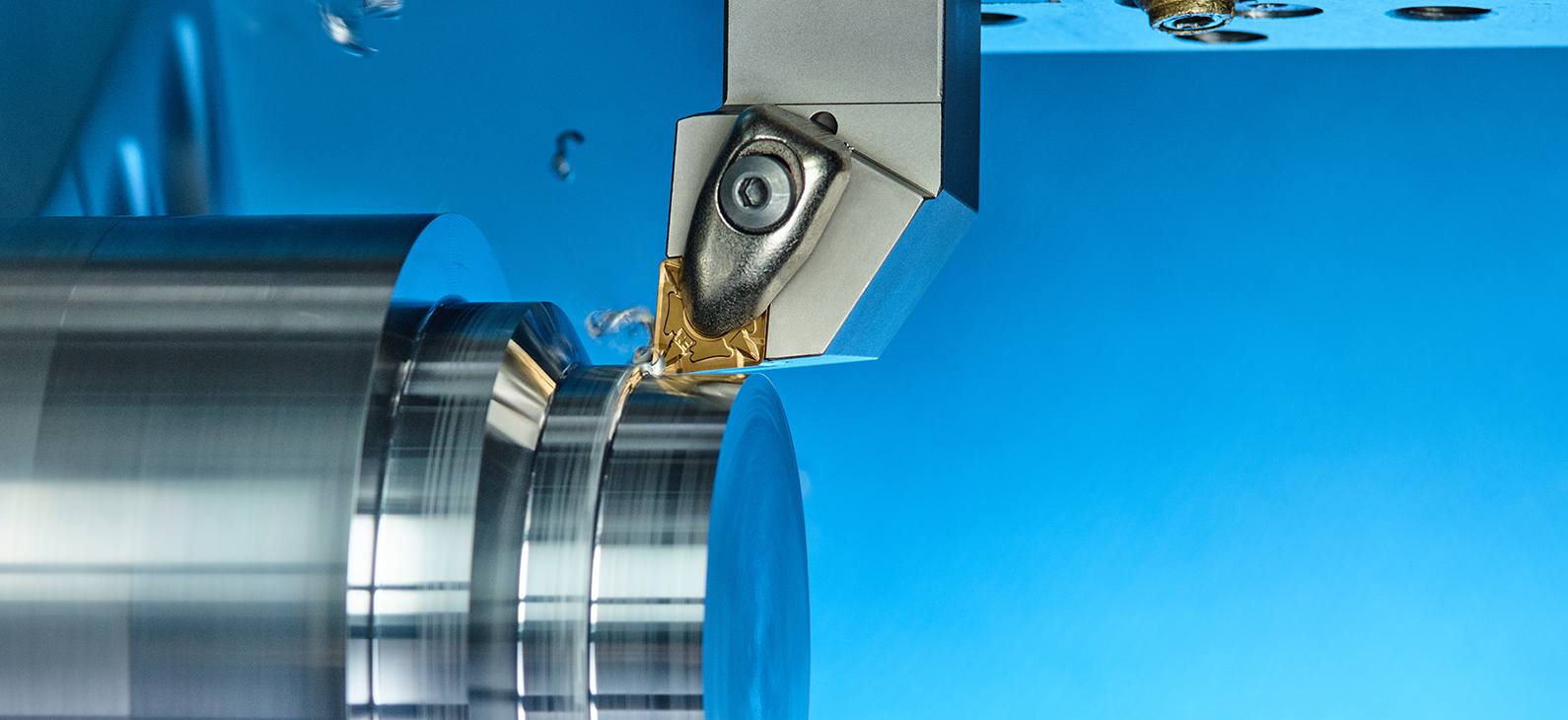

• Significantly improved tool life through advanced anti-adhesion technology

- Delays adhesion due to the optimized cutting edge

- Geometry designed to suppress adhesion propagation

• Stable chip control in the finishing range

- Optimized chip breaking with a side V-shaped cutting edge

- Smooth chip evacuation due to the concave projection design

• Superior dimensional accuracy and surface finish

- Minimized variation between corners through high manufacturing quality

- Strengthened cutting edge by increasing rigidity at the engagement boundary

• Maximized heat dissipation to reduce thermal load

- Optimized cutting edge geometry for coolant inflow (coolant guide)

_영문 복사.png)

_영문 복사.png)