what you’ve wanted for an innovative tooling solution.

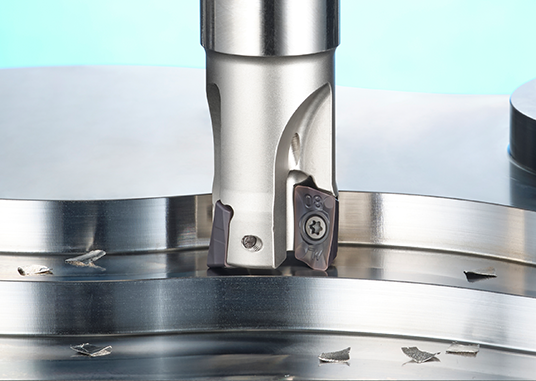

• Improved productivity of heat-resistant alloy processing through improved heat resistance & uniformity

• Control tear resistance and provide stable lifespan by applying high hardness/high lubrication Ultra coating.

UPC830

Heat Resistance Superalloy (HRSA), such as Inconel (Inconel, Waspaloy, Rene) titanium alloy, is a representative material mainly used in the space/aviation industry as it maintains excellent mechanical and chemical properties at high temperatures of 700~1000℃. These heat-resistant alloys show excellent physical properties such as heat resistance, tensile strength, and corrosion resistance, but they place extreme strain on tools during processing, so they are classified as representative heat-resistant alloys (Difficult-to-cut-materials). In addition, heat-resistant alloys have recently been increasingly used as work materials used in the power generation and oil & gas industries.

These heat-resistant alloys have high work hardening properties and low thermal conductivity, so the heat generated during processing cannot escape through the chip and affects the tool, frequently causing the tool's life to end prematurely due to chipping, welding, and sudden breakage. In order to provide a solution for processing heat-resistant alloys, KORLOY has launched UNC805 and UPC810, new Ultra Coating grades with improved welding resistance, chipping resistance, and wear resistance.

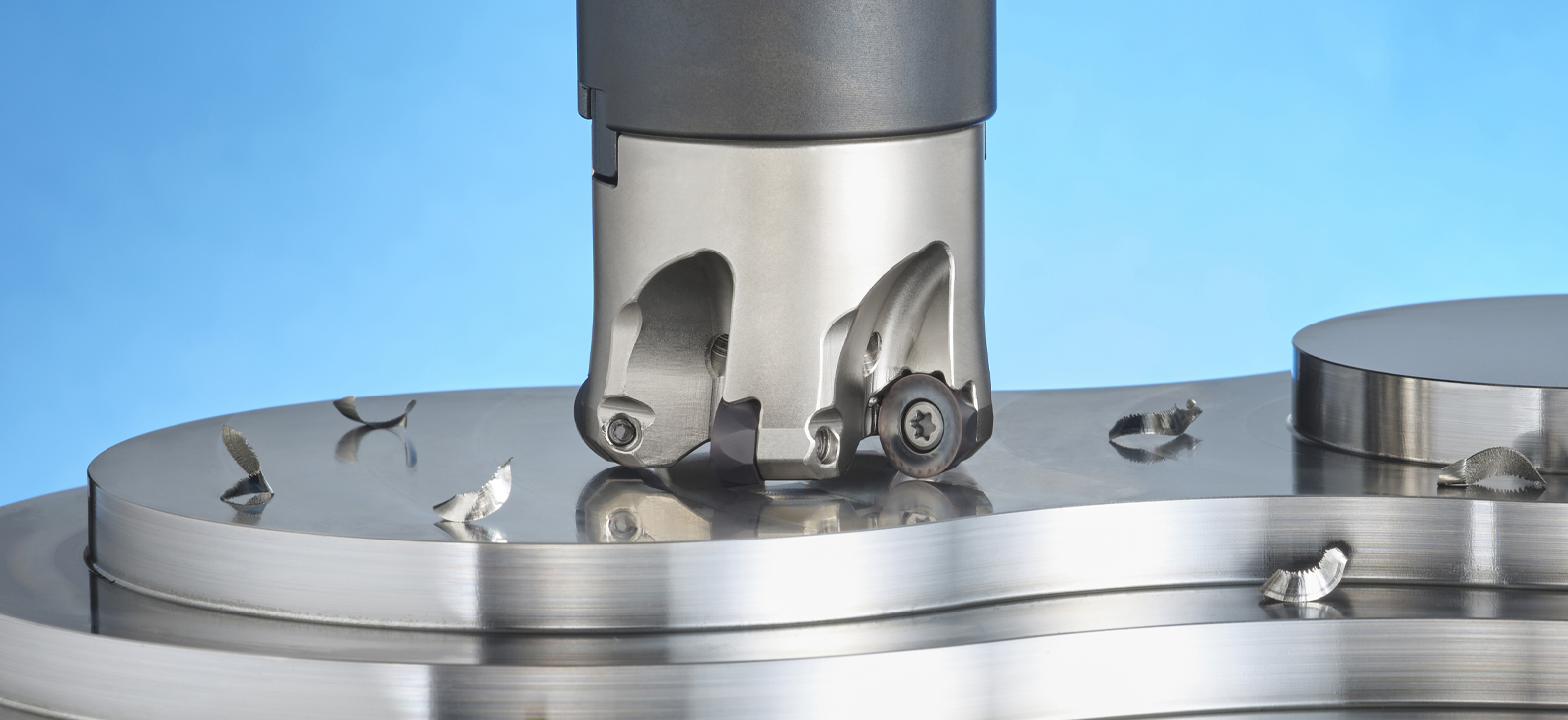

UPC830 is a new milling grade with PVD Ultra Coating applied to a fine-grained base material with improved heat resistance/uniformity. It has superior wear resistance compared to existing products, providing improved productivity and stable tool life when milling heat-resistant alloys.

• Productivity can be improved through high-speed processing of heat-resistant alloys

• Stable lifespan through improved welding/chipping resistance when machining Inconel and titanium alloys