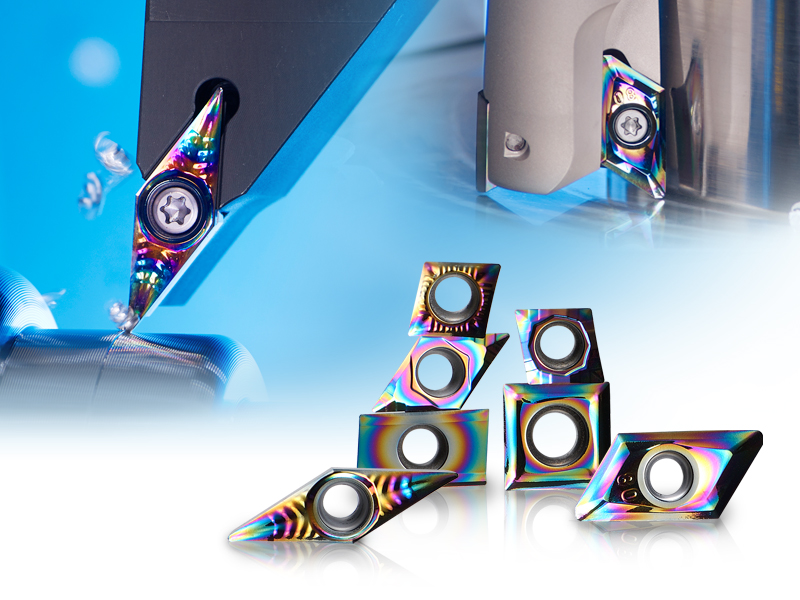

KORLOY has released DLC-coated grades specialized for machining non-ferrous metals - the PD1005 and PD1010.

Non-ferrous metals such as aluminum, copper and magnesium are used extensively across all industries due to its light weight and high conductivity. They also have relatively low fusion points, causing heavy welding on the tool edges during machining. The dulled cutting edges bring about poor surface finish of workpieces while high cutting load increases the chance of sudden chipping, resulting in unstable tool life. As the non-ferrous metal industry has grown rapidly in recent years, there have been increasing demands for complicated workpiece shapes which require highly interrupted machining. In addition, the application of AlSi alloy with high Si content greatly increases material hardness. These changes in the market increased problems such as built-up edges, wear and chipping when machining non-ferrous metals. To meet these challenges, KORLOY has developed the DLC-coated grades with improved resistance to welding, wear and chipping.

This new PD series features DLC (Diamond-Like Carbon) coating which has exceptional resistance to wear and welding similar to those of diamonds, excelling in non-ferrous metal machining. It additionally provides stable tool life due to the highly chipping-resistant substrate.

The PD1005 is a grade for workpieces made of aluminum or copper, and for continuous cutting. The DLC coating with maximized wear and welding resistance enables high speed machining for those materials, delivering excellent surface finish in continuous cutting of general non-ferrous metals.

The PD1010 is a grade for workpieces made of forged aluminum or AlSi alloy, and for interrupted cutting. The combination of the chipping-resistant substrate and DLC coating greatly improves toughness, providing stable and long tool life in interrupted cutting or when machining non-ferrous metals of high hardness.