-

1966-1975

1966-1975

-

1976-1986

1976-1986

-

1987-1993

1987-1993

-

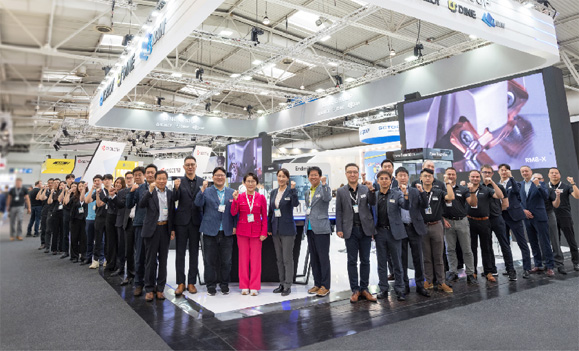

1993-현재

1993-현재

through diversification of

products and

attain the highest quality

In order to the demands for the ever diversified products and the explosive increase in demand for the inserts. By September 1994, Korloy completed the finished powder factory at the Jincheon Factory location. After the completion of the finished powder factory, it was possible not only to secure the vital supply of this materialbut also reduce the dependence on imports. The company completed the finished powder plant in 1994 and first alloy plant in 1995. With its completion, the company achieved the monthly insert production capacity of 1.2 million.

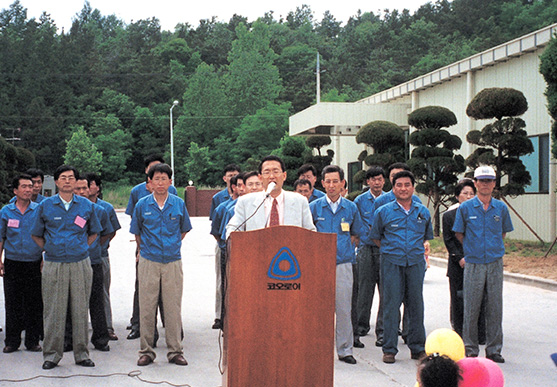

Lim Sang-jin (1981~1996)

from January 1997 to February of the same year, the company went through the preliminary and main evaluation to earn the ISO 9001 certification from the SMICC in march. The scope of certification was KAS 9001(1995), ISO 9001 (1994), EN 2 9001 (1994) and the certification standard was the 'production, designing and installation of inserts and services, production designing and installation of hardmetal tips and services.'

The aluminum processing insert (AK chip breaker, AK insert) which won the IR52 award. IR 52 Jangyeong-sil Award is originality and technical independence among the technical development. The existing technologies could not stop the generation of a tremendous amount of heat or the adhesion of the material to the tool. In this regard, the AK insert of Korloy solves these problems while replacing an imported good.

Korloy established its own agency shop in the 90’s to enter the U.S. market. Continually Korloy aslo established US sales outfit in December 2007, European sales entity in April 2010, India sales entity in November 2011.

as the new CEO of Korloy

in Seocho-dong, Seoul