de alta precisión y dureza

son la solución innovadora que estabas buscando.

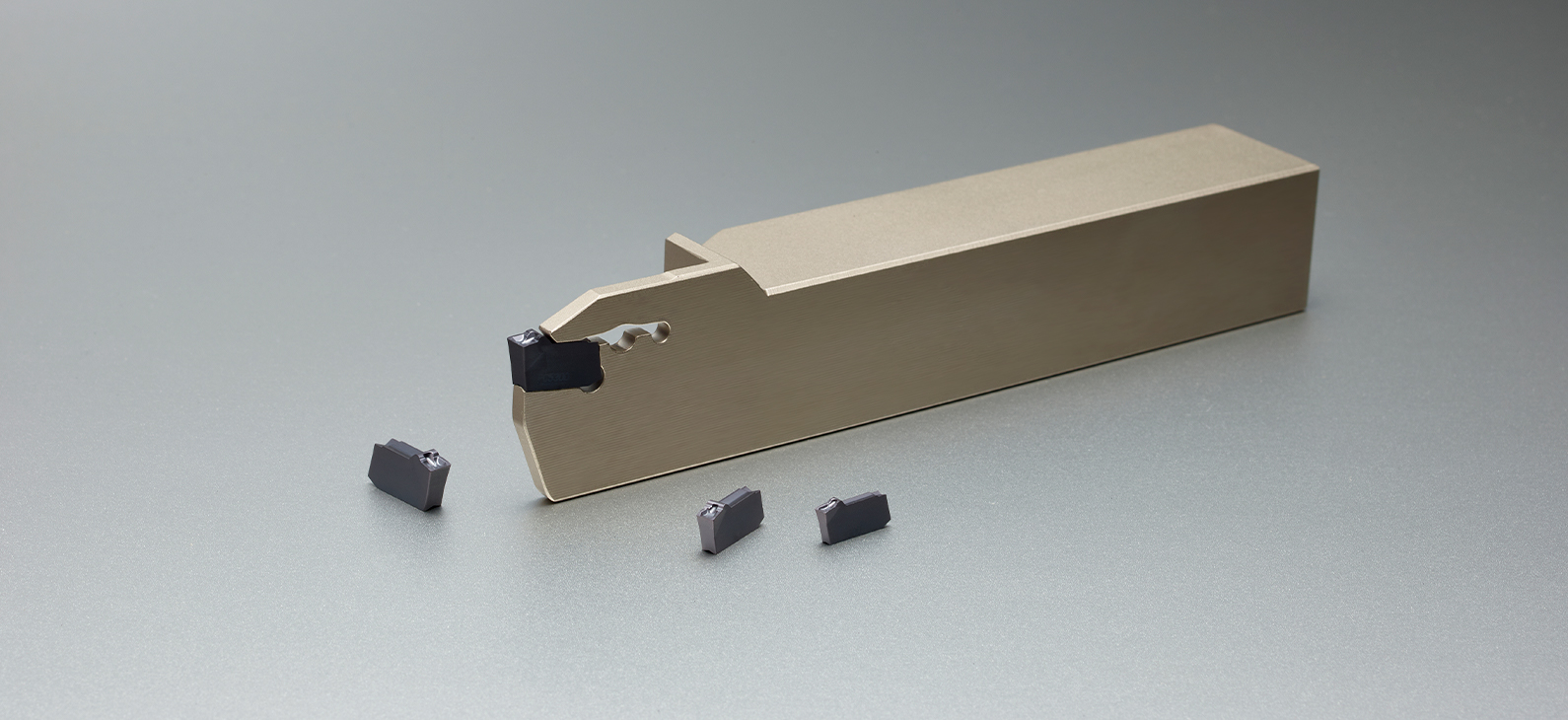

• Improving clamping precision and convenient replacing of insert with using the exclusive wrench.

Saw Man-X

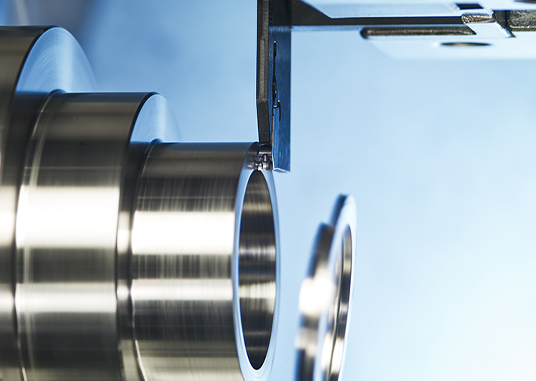

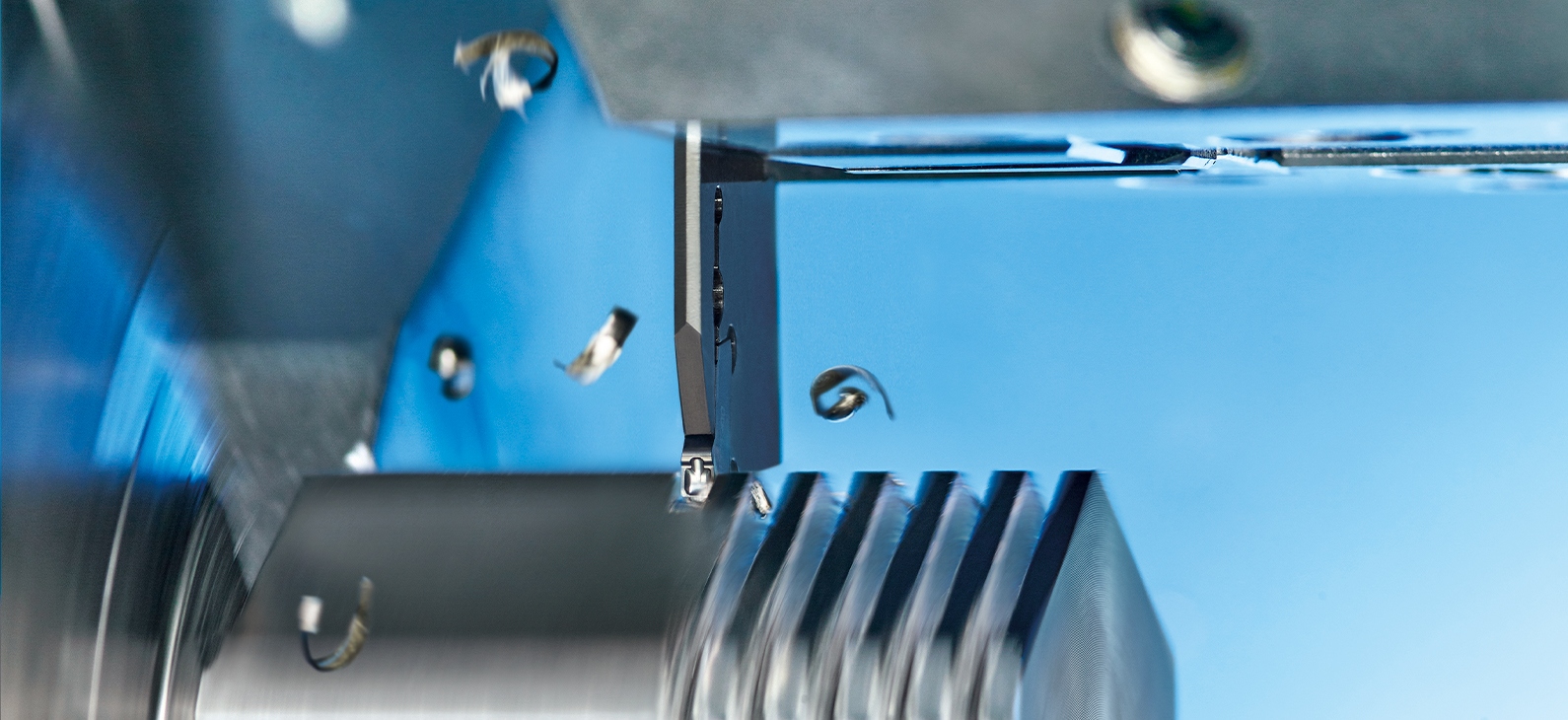

The stable clamping system of an insert and a holder is the most important factor in parting and deep grooving due to vibration from long overhang, and narrow machining width making unexpected fracture of insert and breakage of holder.

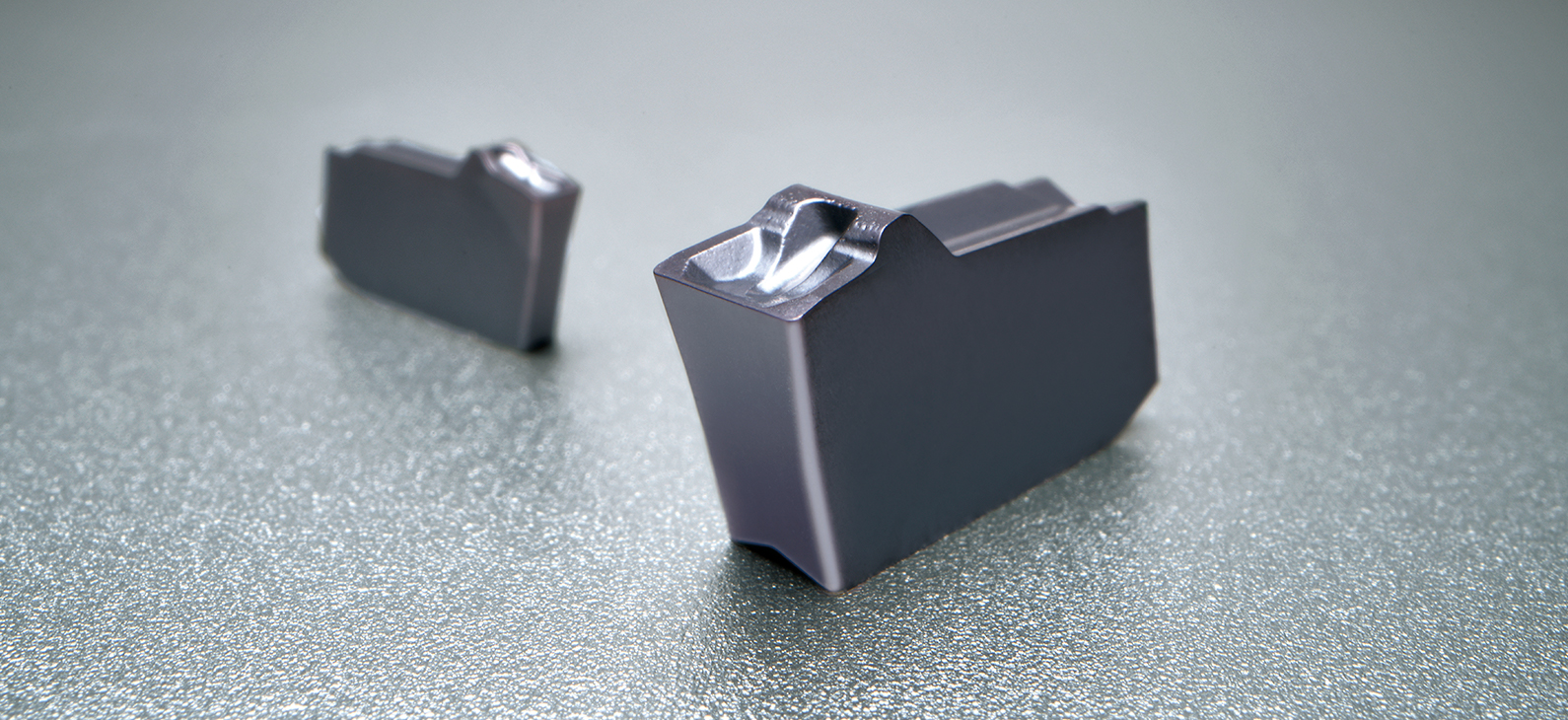

Saw Man-X insert with specially designed three-way (top, bottom and back side) concave V-Rail increases the clamping force. In addition, the optimal chip breaker and bump in the back side of insert reduce chip width effectively and minimize scratch and chip curling due to controlling chip radius.

Saw Man-X holder has strong clamping structure due to three-way convex V-Rail ensuring perfect clamping insert in the seat of holder. Therefore, it realizes stable clamping in high speed and high feed cutting. Especially blade and block with high pressure internal spraying can maximize cooling efficiency when machining HRSA.

In addition, the exclusive self-clamping structure ensures stable clamping and durability of holder in machining with long overhang. The application of stopper in the back side and exclusive wrench increase repeated clamping precision and make replacing insert easy.

Saw Man-X ensures stable quality of machining, long tool life and convenient clamping system in high speed and high feed machining due to applying three-way V-Rail shape, differentiated chip breaker design and exclusive wrench. Through these advantages, Saw Man-X provides effective and economical solutions in parting and deep grooving.

• Stable clamping system in high speed and high feed machining

- Three-way V-Rail structure

• Optimal chip breaker by workpieces

- N Chip breaker : steel, cast iron

- S Chip breaker : Stainless steel, HRSA

• Enhanced convenience in insert replacement

- Using the exclusive wrench

• More efficient cooling in applying high pressure inner coolant

- 2 channel direct spraying on cutting edge

- Longer tool life in HRSA cutting

.jpg)

.jpg)

_1_retouch.jpg)

and S_1_retouch-55.jpg)