In the pipe industry where dry machining is applied mostly to large structures, the main reasons of tool failure are breakage on the coating by physical impact and thermal cracks. Under this cutting condition, cutting edges with high toughness and high thermal crack resistance are needed in order to prevent breakage and endure radical thermal change.

The thermal crack resistance is decided by heat conductivity of the substrate, thermal insulation of the coating, and coefficient of thermal expansion.

Our new milling grades for pipe industry, NC5340 and NC5350, have high toughness, high thermal crack resistance and strong blade in its specially designed substrate and CVD coating with excellent thermal insulation.

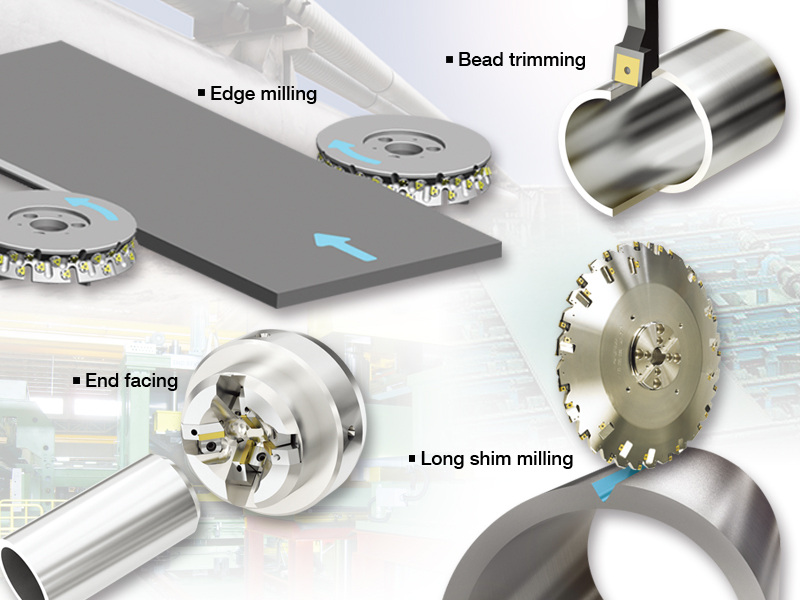

You might see the remarkably extended tool life of our products during edge milling and terminal fitting cutting where thermal change is the most rapid.

A special honing treatment on the land prevents sudden breakage on blades and enhances anti chipping for longer tool life.

In case of removing bids and machining on long rolls, our existing product, PC5300 and NC5330, are recommended. The 2nd recommended grade with high toughness is NC5340.

KORLOY’s recommendations for pipe industry will provide the best solution for improved productivity and flexible choice.